Our Advanced Machinery

State-of-the-art printing equipment from industry leaders ensures vibrant colors, sharp details, and precise results for every project.

Komori Super Lithrone LS426 (2 Units)

Sheet-Fed Offset Press - 4-Color

The Komori Super Lithrone LS426 is prized in commercial printing for its robust performance and precision. Ideal for high-quality marketing materials, brochures, and publications requiring full-color printing.

Key Features:

• Automated systems for quick plate changes and color management

• Reduced setup times with vibrant output from first to last sheet

• Handles various paper sizes and thicknesses with speed and accuracy

• Built on reliability for consistent commercial printing results

Komori Super Lithrone LS529+Coater

Versatile 5-Color Offset Press with Inline Coater

The Komori Super Lithrone LS529 offers expanded capabilities over standard 4-color models. The fifth unit can be used for spot colors (Pantone shades) or special varnish, while the integrated inline coater applies protective or decorative aqueous or UV coating in a single pass.

Applications:

• Luxury packaging with enhanced durability and visual appeal

• High-end catalogs and magazine covers

• Premium products with gloss or matte finish

• All-in-one process for highly efficient production

Heidelberg 2-Color

Heidelberg is a benchmark for quality in the printing industry, and its 2-color presses are workhorses for jobs that don't require a full-color spectrum. These machines are ideal for printing items like business cards, letterheads, invoices, and newsletters using two specific ink colors (e.g., black and a corporate brand color). They are renowned for their exceptional registration accuracy, durability, and consistent output, making them a reliable and economical choice for high-volume, two-color work.

Perfect Cutting Machine (4 Units)

A perfect cutting machine, often a brand like Perfecta, is a critical component in any print shop for finishing. This industrial guillotine is used to trim large printed sheets down to their final size with extreme accuracy and a perfectly smooth edge. Modern cutters are highly automated, allowing an operator to input specific dimensions for a job. The machine then automatically positions the paper stack and performs a series of precise cuts, ensuring that every piece, from business cards to book pages, is uniform.

Lamination Machine (2 Units)

A lamination machine is a finishing tool used to apply a thin layer of plastic film to paper or cardstock, adding strength and a high-quality finish. The process can use heat (thermal lamination) or pressure to adhere the film. Common finishes include gloss, which makes colors appear more vibrant; matte, which provides an elegant, non-reflective surface; and soft-touch, which offers a unique velvety texture. Lamination protects prints from moisture, tearing, and handling.

Perfect Binding Machine

Perfect binding is the method used to create professional-looking softcover books, such as paperbacks, manuals, and thick reports. The process involves collating the pages into a block, grinding the spine edge to roughen it for better adhesion, and then applying a strong, hot-melt glue. A wrap-around paper cover is then attached to the glued spine. The result is a clean, flat, and printable spine, giving the final product a high-quality, "perfect" appearance.

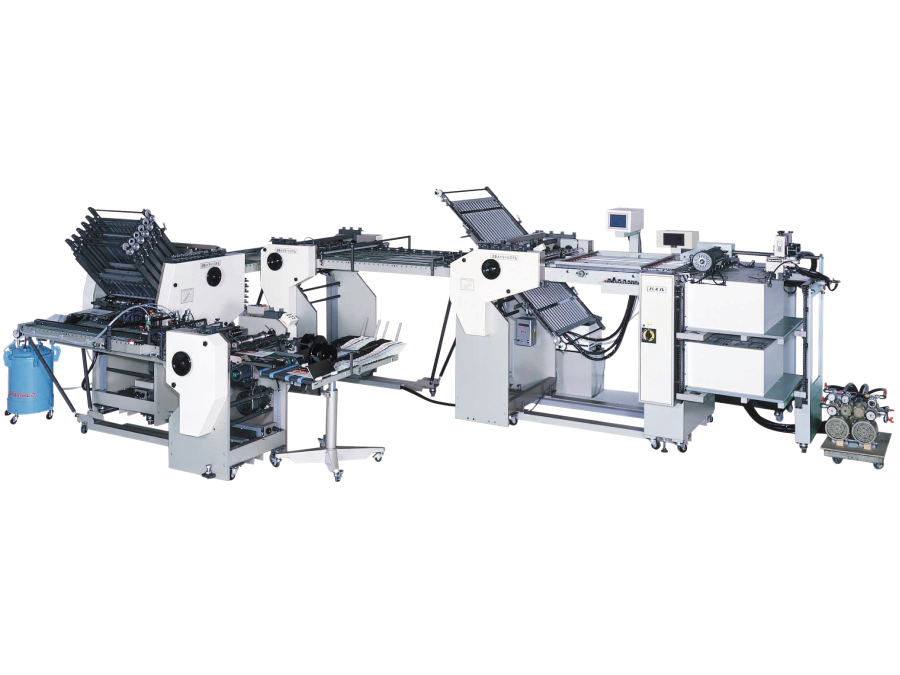

Folding Machine (2 Units)

An industrial folding machine is essential for materials like brochures, mailers, and inserts. These machines can perform a wide variety of fold types, from a simple half-fold to more complex styles like letter folds (tri-fold), Z-folds, gatefolds, and accordion folds. They use a system of rollers and adjustable plates (buckles) to create crisp, consistent folds at high speeds, a task that would be incredibly time-consuming and inconsistent if done by hand.

Punching Machine (3 Units)

A punching machine, often a platen press, is a form of die-cutter used for creating custom shapes and designs in paper, cardstock, or corrugated board. A custom-made die, which is essentially a sharp blade bent into the desired shape, is pressed with immense force onto the material. This allows for the mass production of items like custom-shaped packaging boxes, pocket folders, unique marketing pieces, and labels.

Center Pinning Machine (4 Units)

A center pinning machine, more commonly known in the industry as a saddle-pinning, is used for a popular and economical binding method. Collated sheets are draped over a "pinning" and wire staples (pins) are driven through the centermost fold and clinched shut on the inside. This process is ideal for creating booklets, catalogs, magazines, and programs that have a relatively small page count.

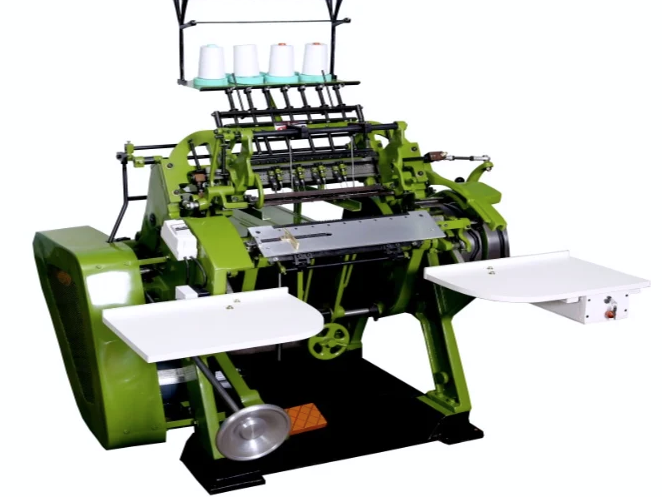

Saddle Stitching Machine

A saddle stitching machine binds documents by inserting wire staples through the spine of folded and collated pages. The term "saddle" comes from the part of the machine that the sheets are placed over during the stitching process. This method is fast, cost-effective, and ideal for publications with a lower page count, such as brochures, calendars, and thin magazines. The booklets can open flat, making them easy to read.